Composite Research is an Italian startup that invented and patented MADFLEX, a multilayered material that:

- is lightweight and flexible;

- provides acoustic and thermal isolation;

- protects from vibrations;

- is highly resistant.

How does this revolutionary technology substitute welding?

Madflex Patch Repair (link to tech spec or video)

Ventures Bridge is supporting Composite Research in their internationalization process and the marketing expansion of Madflex Patch Repair – a flexible resistant, air proof and leak proof tape that repairs industrial pipes. Made with the MADFLEX technology, this tape literally substitutes an often complex welding process with amazing results.

Taking on the Oil & Gas sector like a storm.

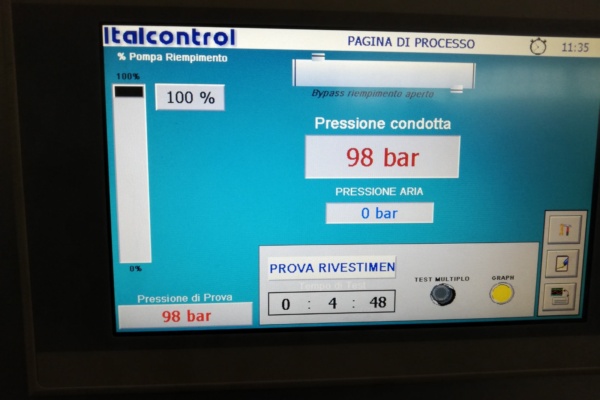

The applications and uses of the MADFLEX technology are not only limited to the PATCH REPAIR product, which is a real game changer in intricate industrial plants. The market push is now focussed on the Oil & Gas sector and the product certification is being completed in partnership with ItalGas, An Italian giant and market leader in the Oil & Gas sector.

Those impossible to reach places where welding is costly and complicated can now be solved with almost miraculous simplicity. Until today, repairing pipe leaks in small or big industrial plants was not feasible without shutting down an entire production line or even dismantling one part of a machine to fix another part. Madflex Patch Repair is like tape and acts like welding.

Infinite potential across industrial sectors

The MADFLEX composite materials are used in numerous industries:

- in the automative and aeronautical sectors for interior furnishings

- in the Oil & Gas sector repairing pipes without welding and instead using adhesive patches

- in the medical field to build orthopaedic wheelchairs and stretchers

- for construction creating lightweight, durable panels.

Madflex has been used to build sturdy suitcases, create waterproof flexible hinges, in medical devices for heart massage and for bio degradable utensils in the food and beverage industry.

If you want to know how MADFLEX technology can improve your industry, contact us here